Fischer Tropsch Catalyst Testing Project

Customer objective

Our customer asked us to run a catalyst improvement program by testing some 500 catalysts. The prerequisite to the study was that the various experiments should be easily reproducible.

Our approach

Experiments were carried out in our proprietary 64 reactor Flowrence® systems. Because high alpha waxes formed during the Fischer Tropsch reaction, we needed to control gas/liquid separation at high temperatures.

The tests included:

- Feed:

- Syngas (different ratios of H2/CO) and additional feeding of water

- Process conditions:

- 150-550°C; 10-100 barg

- GHSV up to 100,000 h-1

- Online analysis of gas phase products up to C12

- Offline analysis of liquid products (waxes)

Value created

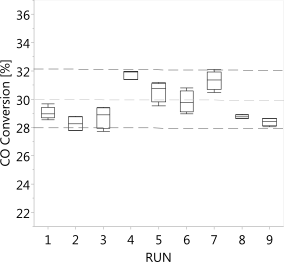

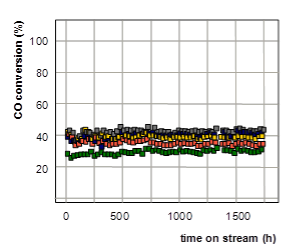

Using a 64 reactor Flowrence® systems to test more than 500 new catalysts in 9 individual experiments, we discovered a minimal inter-experiment variability. This approach allowed us to easily compare catalysts across different experiments, resulting in the identification of several promising leads that later were tested at a larger scale.